This blog is about the most important aspect of sales and inventory control.

Don’t get me wrong, there are a lot of important steps and procedures a manager or owner must do and put in place to make sure his or her inventory and sales are correct and nothing is missing. And if I want to be literal, clearly locking the doors at nighttime is the most important step!

But realistically, there is simply just one event that must be done. This is the one event that makes the difference between knowing if you are running a tight ship or if you are missing anywhere from 10% to 50% of your sales. This is the one most single important event that trumps all others. I’ll go into examples.

And again, we can list a few of the things that can be done differently that contribute to an accurately counted inventory and knowing how much is being used and how much is missing. But there is just one event over all others that must be done.

For the period you are measuring, you must calculate your ideal sales, costs, percentages and quantity’s and compare those numbers to the same values for the actual numbers for sales, costs and percentages and quantity’s. This is the Tipping Point between knowing and not knowing if you are missing inventory and sales!

If you don’t do this comparison, you will absolutely not know how much is missing. And those who don’t do this comparison are missing between 10% and 50% of their sales. No exception.

No amount of experience, time spent at the bar or in the kitchen, watching video or gut level feeling will be able to tell you nearly as accurately how much in sales you are missing. Unless, of course you are the only person touching the inventory all the time and ringing up all the sales. That means you are a one man show. No employees.

Here’s why. Most restaurant operators count their inventory. That’s a given. Not all do it the same. So there are some differences that make for a more accurate inventory. Some count only once a month. Some only count what’s in the stockroom. Some weigh the bottles, some tenth them. Some shake the kegs, some weigh them, and some use flow meters. Some pull the bottles of beer out of the coolers, some guess. Some figure out their inventory usage by just adding the invoices together for the period of time they are measuring. That of course, doesn’t take into account the variable amount of inventory on hand either for the beginning or the ending of the period. Some guesstimate how much meat is on hand, others count, some weigh.

And do they practice portion control? What kind of POS or register system is used? And how is it programmed. Who does the counting? How are the invoices entered? Who checks the work? These are all variables.

But not calculating the Ideal numbers for cost percentages (Pour or food cost), costs used, sales doesn’t allow you to compare what did happen (actual) to what should have happened (Ideal).

To calculate the Ideals, you need to convert the sales rung up in the register or POS system to the equivalent costs and quantities used of inventory and what ideal amount of sales should be in dollars. To do this, you will need a software program. Not an excel spreadsheet. And a POS system only generates the sales report. Unless your POS has an inventory management software module, it by itself is not enough.

To do the calculations, the Inventory and Sales Management Software program needs to have each menu item programmed with the brands used and the quantities used for each menu item. This takes a lot of effort, but it’s worth it!

Then you import into the program the actual sales dollars and actual sales quantities.

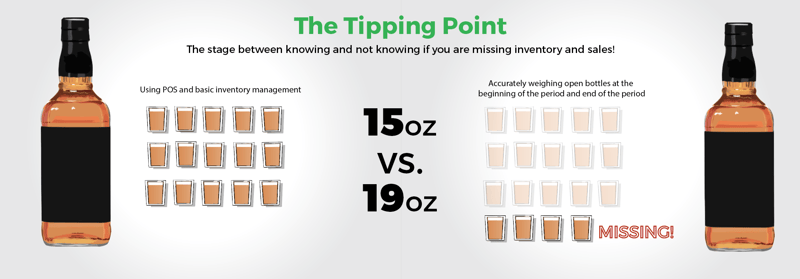

Example. 10 shots of Jack Daniels was sold at $4.50 each for a total sales amount of $45.00. This information is from the Product Mix Report from the POS system. The Inventory Management software program will then calculate that with a standard pour size of 1.50 ounces that 15 ounces of Jack should have been used. And with each shot of Jack costing $1.43; that means $14.43 of Jack should have been used and the cost percentage should be 31.9%. By taking the actual inventory by accurately weighing the bottle at the beginning of the period and end of the period, it’s determined that 19 ounces of jack was used. So $18.16 of Jack was used and the actual cost percentage is 40.4%. Not 31.9%. And 4 ounces of Jack is missing. That ability to do the comparison and that information is The Tipping Point!

That is the single biggest difference between what you can do and what the majority of operators are not doing. Sure, weighing the bottles is better and more accurate. But I’m still tracking usage, just not as accurately. But failing to compare the Ideal numbers to the actual numbers would be like NOT counting out your cash drawer and comparing your on-hand cash count to what should be in the drawer as defined by the Z tape or Cash In Drawer report. How many of you would operate your restaurant and not balance out the drawer at least once a day, if not after every shift change? How smart would that be? By not comparing your actuals to your ideals for sales and inventory, it’s like comparing your actual cash count for this Monday to your actual cash count for last Monday and determining if your drawer is short or over because your cash count didn’t match up this week with what was there last week! That would be a joke if you did that!

There are quite a few Inventory Software Management programs out there. Some are better than others. Some only work with a few POS systems, some work with all of them. There is even a company that will do everything for you or train your staff to do it in-house, using their software program.

Just getting the program isn’t enough. You will need to set up the database and you will need to update the costs as they change.

*This article was originally written posted on LinkedIn by Sculpture Hospitality Expert, Charlie Deibel.

.png)